Page 211 - International safety guide for oil tankers and terminals

P. 211

SHIPBOARD OPERATIONS

---ใช้เพื่อการศึกษาเท่านั้น---

All dimensions are in millimetres

Stud perpendicular to

presentation flanges

งานห้องสมุด ศูนย์ฝกพาณิชย์นาวี

25.4

50

500

800

yellow

100 100

red red

16 mm diameter hole in inboard end of reducer

and in hose flange to accept stud

12.7 mm diameter stud ึ

at 12 o’clock position

on presentation

flange

VAPOUR to be stencilled

on side at 10 o’clock and

2 o’clock positions

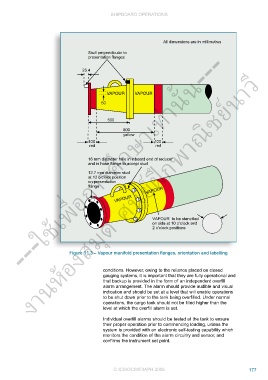

Figure 11.3 – Vapour manifold presentation flanges, orientation and labelling

conditions. However, owing to the reliance placed on closed

gauging systems, it is important that they are fully operational and

that backup is provided in the form of an independent overfill

alarm arrangement. The alarm should provide audible and visual

indication and should be set at a level that will enable operations

to be shut down prior to the tank being overfilled. Under normal

operations, the cargo tank should not be filled higher than the

level at which the overfill alarm is set.

Individual overfill alarms should be tested at the tank to ensure

their proper operation prior to commencing loading, unless the

system is provided with an electronic self-testing capability which

monitors the condition of the alarm circuitry and sensor, and

confirms the instrument set point.

© ICS/OCIMF/IAPH 2006 177