Page 160 - International safety guide for oil tankers and terminals

P. 160

INTERNATIONAL SAFETY GUIDE FOR OIL TANKERS AND TERMINALS

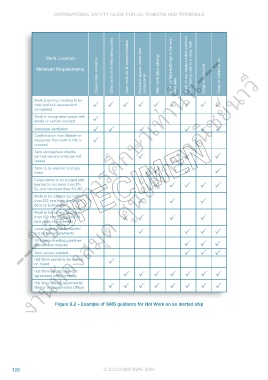

non-hazardous area accommodation

Work to be carried out moreื่อการศึกษาเท่านั้น---

Work Location

Engine room workshop Other parts of Open deck aft of pumprooms) Main deck (deck plating) deck area Cargo pumprooms Cargo or ballast tanks

Hot Work permit issued inงสมุด ศูนย์ฝกพาณิชย์นาวี

Minimum Requirements Enclosed spaces (other than Work on fixtures/fittings in the main Work on any cargo-related pipelines heating coils in a cargo tank

Work planning meeting to be incl.

held and risk assessment

completed

Work in designated space with

shield or curtain erected

Adequate ventilation

Confirmation from Master or

designate that work is OK to

SPECIMEN

proceed

Tank atmosphere checks

carried out and entry permit

issued

Tank to be washed and gas

freed ึ

Cargo tanks to be purged and

inerted to not more than 8%

O 2 and not more than 2% HC

---ใช้เพ

Work to be carried out further

than 500 mm from the tank

deck or bulkheads

than 500 mm from a fuel oil

tank deck or bulkheads

Local cleaning to be carried

out as per requirements

All interconnecting pipelines

flushed and drained

งานห้อ .

Tank valves isolated

Hot Work permit to be issued

on board

agreement with Company

Hot Work permit approved by

Master or Responsible Officer

Figure 9.2 – Example of SMS guidance for Hot Work on an inerted ship

126 © ICS/OCIMF/IAPH 2006