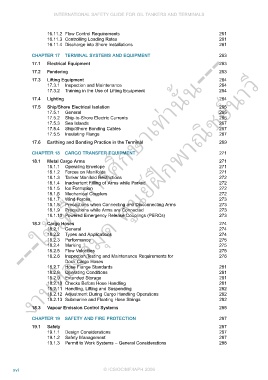

Page 16 - International safety guide for oil tankers and terminals

P. 16

INTERNATIONAL SAFETY GUIDE FOR OIL TANKERS AND TERMINALS

16.11.2 Flow Control Requirements 261

16.11.3 Controlling Loading Rates 261

18.2.1้เพื่อการศึกษาเท่านั้น---

16.11.4 Discharge into Shore Installations 261

CHAPTER 17 TERMINAL SYSTEMS AND EQUIPMENT 263

17.1 Electrical Equipment 263

17.2 Fendering 263

17.3 Lifting Equipment 264

17.3.1 Inspection and Maintenance 264

264

17.3.2 Training in the Use of Lifting Equipment 267ย์นาวี

17.4 Lighting 264

17.5 Ship/Shore Electrical Isolation 265

17.5.1 General 265

17.5.2 Ship-to-Shore Electric Currents 265

17.5.3 Sea Islands

17.5.4 Ship/Shore Bonding Cables 267

17.5.5 Insulating Flange 267

17.6 Earthing and Bonding Practice in the Terminal 269

CHAPTER 18 CARGO TRANSFER EQUIPMENT 271

18.1 Metal Cargo Arms 271

18.1.1 Operating Envelope 271

18.1.2 Forces on Manifolds ึ 271

18.1.3 Flow Velocities มุด ศูนย์ฝกพาณิช 272

Tanker Manifold Restrictions

18.1.4 Inadvertent Filling of Arms while Parked 272

18.1.5 Ice Formation 272

18.1.6 Mechanical Couplers 272

18.1.7 Wind Forces 273

18.1.8 Precautions when Connecting and Disconnecting Arms 273

273

18.1.9 Precautions while Arms are Connected 274

---ใช 18.2.2 Types and Applications 274

273

18.1.10 Powered Emergency Release Couplings (PERCs)

Cargo Hoses

18.2

274

General

18.3านห้องส

Performance

18.2.3

275

275

Marking

18.2.4

275

18.2.5

276

18.2.6

Inspection,Testing and Maintenance Requirements for

Dock Cargo Hoses

Hose Flange Standards

281

18.2.7

281

Operating Conditions

18.2.8

281

18.2.10 Checks Before Hose Handling

282

18.2.11 Handling, Lifting and Suspending

ง 18.2.9 Extended Storage 281

282

18.2.12 Adjustment During Cargo Handling Operations

282

18.2.13 Submarine and Floating Hose Strings

285

Vapour Emission Control Systems

CHAPTER 19 SAFETY AND FIRE PROTECTION 287

19.1 Safety 287

19.1.1 Design Considerations 287

19.1.2 Safety Management 287

19.1.3 Permit to Work Systems – General Considerations 288

xvi © ICS/OCIMF/IAPH 2006